Understanding Industry 4.0 and ERP in the Manufacturing Industry

Like it or not, we’re in the middle of a massive transformation regarding the way we make things, thanks to the digitisation and automation of manufacturing we’ve come to know as Industry 4.0. Industry 4.0 represents the fourth revolution of manufacturing: the adoption of computers and automation, enhanced with smart and autonomous systems and fueled by data and machine learning.

The power that data gives to business decision-makers to better understand customer behaviour and business operations means manufacturers are prioritising the capture and analysis of data through internet-connected devices on the shop floor. These connected, ‘smart’ factories are on the rise throughout the manufacturing industry.

However, access to large amounts of information is not enough. Manufacturers need to gain insight, make better decisions, and drive business outcomes through the correct analysis and use of that data through IoT technologies.

But first, here’s how manufacturers are using IoT tech on the shop floor:

- Automated production. IoT technology allows all equipment within a factory to be connected or linked under one dynamic base of data. Decision trees can be automated and analysis performed at a rate faster than humanly possible. Functions such as machine operation, scheduling, staffing and work in process can be automated, thanks to IoT technology.

- Predictive maintenance. Industry 4.0 sees the rise of predictive – rather than preventative – maintenance. Predictive maintenance reduces high potential production loss due to machine failure by preemptively detecting problems, scheduling repairs, managing the order of spare parts and recommending maintenance.

- Supply Chain. From managing raw materials shipments, making autonomous decisions, to accurately manage inventory, IoT technology utilises data that is gathered from production equipment to more accurately trace, track and consume materials efficiently and cost-effectively.

Industry 4.0 and ERP

Understanding the power of Industry 4.0, and the critical role ERP plays within it, is a priority for forward-thinking manufacturers.

Before the emergence of modern ERP systems, small to medium-sized manufacturing operations were a tangle of mute machines, patchwork software platforms and siloed processes.

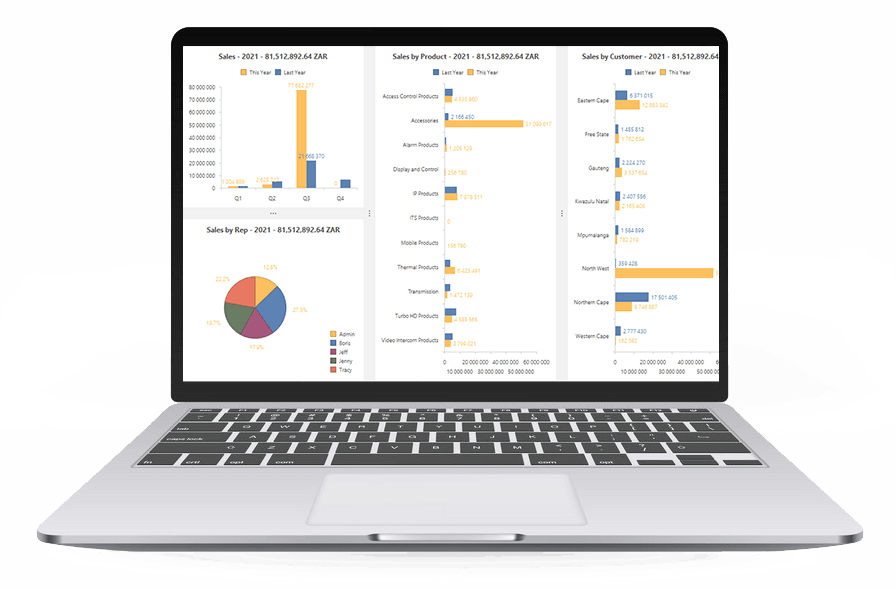

ERP or business operating systems (BOS) allow all equipment, staff and operations to be centrally integrated into one system, even with multi-location, multi-currency scenarios. This means transactions and records are updated in real-time, allowing for shared operations and transaction data to be captured and analysed for powerful insight and business intelligence.

This all translates into improved business operations, productivity, and greater profitability.

For those who don’t already know, ERP solutions are at the core of business data collection and processing, and when this is harnessed correctly can be pivotal in gaining a competitive advantage. IDC research shows that 85% of large manufacturers name ERP as their main platform for delivering positive customer experiences.

ERP systems provide higher productivity by consolidating business processes under one database, as well as improve accuracy in transactions, speed of reporting, and greater business agility.

It allows for accurate decision making with clearer insights into the business, while simplifying IT efforts and streamlining complex business operations.

Due to ERP’s inherent data processing and automation capabilities, and the fact that BOS solutions can connect to the cloud and any internet-enabled device, ERP facilitates the adoption of Industry 4.0 advances in manufacturing.

There are several reasons why Industry 4.0 and ERP compliment each other:

- Data Integration. ERP solves two of the main challenges Industry 4.0 faces in manufacturing: machines that are ‘silent’ or not connected, and siloed business departments / processes. ERPs “un-silo” business data and integrate that data into a single database that is programmed across the enterprise to manage all aspects of the operation.

- Data Interpretation. Most ERP systems are modular and customisable. This makes them ideal as the infrastructure for installed IoT devices, as these can be programmed to fit that modularity. Particularly for a’ la carte ERP systems that are cloud based, where functionality is customisable for the user to meet their particular manufacturing reality. Most ERP systems can facilitate the interpretation of this vast amount of data through their reporting functionality, allowing for decentralised decision making.

- Security. Many IoT service providers do not have native security systems where most manufacturing companies that use ERP systems already have security settings within the ERP system itself to manage the flow of data throughout the business. Having integrated finance, production management, HR, management reporting and CRM functions, where confidentiality and security are critical, they have already secured who has access to data in key functional areas.

ERP, Manufacturing, and the Future

There have been many positive developments in ERP for manufacturing businesses in recent years, such as cloud-based availability and data management, customisability, continuous updates and more. They are ideal for small to medium-sized manufacturers who may not have the resources to pursue the more expensive larger providers.

Industry 4.0 is a natural fit with BOS or ERP because it reduces deployment time, staff training, and data and metric reconciliation between departments, and it allows for a higher degree of automation, autonomous decision making, and intuitive and focused machine learning to ramp up the core ERPs capabilities.

If Industry 4.0 is the next data “superhighway”, then ERP systems that group and organise that data are the infrastructure components upon which that highway is built.