How ERP Benefits Industry 4.0 in the Manufacturing Industry

The influx of new technology in the workplace is transforming the way we work; automation, digitisation, machine learning and artificial intelligence all promise greater benefits to organisations. This is called Industry 4.0. But while business leaders are trying to keep up with the flood of new technologies, there is one application that has been a vital tool in the manufacturer’s arsenal for the past 50 years. This application streamlines complex business operations and improves efficiencies across entire supply chains, and continues to evolve in order to stay abreast with, and seamlessly integrate with, newly developed technologies.

This one application is the Enterprise Resource Planning (ERP) system. Manufacturers have used it for decades, and it still remains the next big thing in Industry 4.0.

Smart factories and boosted efficiency

According to Forbes, by 2022, smart factories will enable a 7x increase in overall productivity, potentially adding $500B to $1.5T in value-added to the global economy. 76% of manufacturers are either in a smart factory initiative or are in the process of developing one.

Helmuth Ludwig, CEO, Siemens Industry Sector, North America, says, “This is nothing less than a paradigm shift in the industry: the real manufacturing world is converging with the digital manufacturing world to enable organizations to digitally plan and project the entire lifecycle of products and production facilities.”

Before the Internet of Things (IoT) enabled machines to be connected and have a ‘voice’ to relay their current state, temperature, performance, and so on, the industrial value chain (including product design, production planning, production engineering, production execution and services) was implemented in isolation of each other. Today, smart factories see the convergence of all of these into an integrated system for improved efficiency, less waste, and a more profitable manufacturing endeavour.

Smart factories boost productivity by enabling shorter product runs, allowing for the manufacturing of more complex products with more frequent material changes. This results in faster deliveries, alternatives of packaging and distribution, and more effective change forecasting, supply chain management, and product traceability.

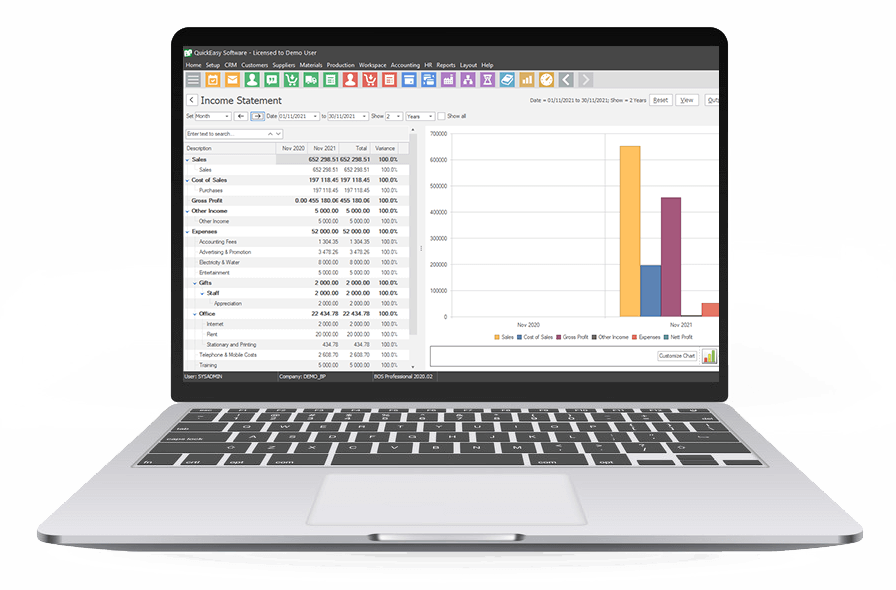

When manufacturers combine the inbuilt processing capabilities that ERP brings: the seamless integration of planning, materials management and procurement, manufacturing, financial and business intelligence in one single system, they harness the full value of technologies to meet greater business objectives.

Industry 4.0 and ERP provide complete factory automation and integrate multiple business processes and disconnected systems to better unite all aspects of the supply chain. This reduces manual tasks and human interventions and allows business leaders to spend more time focusing on product innovation and servitization.

Robotics and automation

Industry 4.0 sees the dawn of automation and robotics in manufacturing, with the promise of improved machine uptime, lowered labour costs, consolidated factory space and reductions in capital expenditure. However, with the new technology comes new learning for staff and employees, and the need for a system to manage it.

By linking robotics to your ERP system, and integrating that data with the ERP data, manufacturers are better able to measure robot productivity and schedule downtime or maintenance in order to manage production. ERP also provides valuable costing information and clarity on how profitable the machine is.

The Internet of Things and ERP

Many manufacturers have fitted sensors to their machines in order to analyse performance, safety levels, durability and other key metrics. This information is sent directly to their ERP solution, which automatically updates the Bills of Materials, adjusts design specifications and adjusts processes to continually improve products through production.

The use of sensors in manufacturing production is not a new concept, but the use of ERP to route and process the masses of data collected by the sensors and then feed this data into design and engineering processes helps manufacturers in their drive towards continuous improvement.

In conclusion

Industry 4.0 and ERP offer the same benefits to manufacturers that will ensure they remain competitive and relevant in this changing landscape: greater productivity, improved efficiency and higher flexibility.

Manufacturers who continue to use ERP as a business-critical supply chain tool, while innovating around how they will maximise its application in their own businesses, will thrive in this ever-changing, smarter, more connected landscape.

Considering the leaps in development that ERP has made over the last 50 years, the next 50 years promise to be exciting territory indeed.